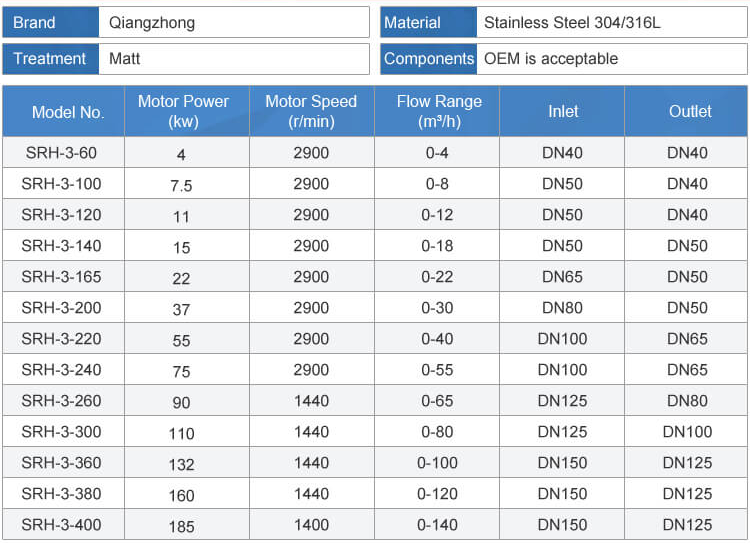

Sigogin samfura

* Bayanin da ke sama don tunani ne kawai kuma ana iya daidaita shi gwargwadon bukatun abokan ciniki.

* Wannan kayan aikin za a iya daidaita su gwargwadon yanayin albarkatun ƙasa don biyan buƙatun tsari, kamar su ɗanɗano mafi girma, haɗuwa da sauran buƙatu.

Tsarin Samfura

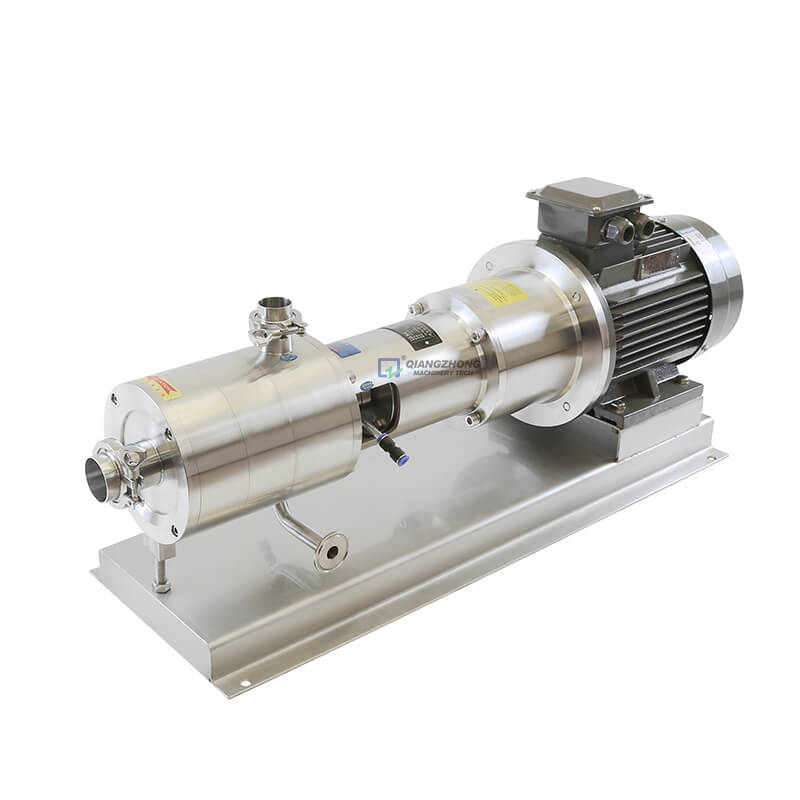

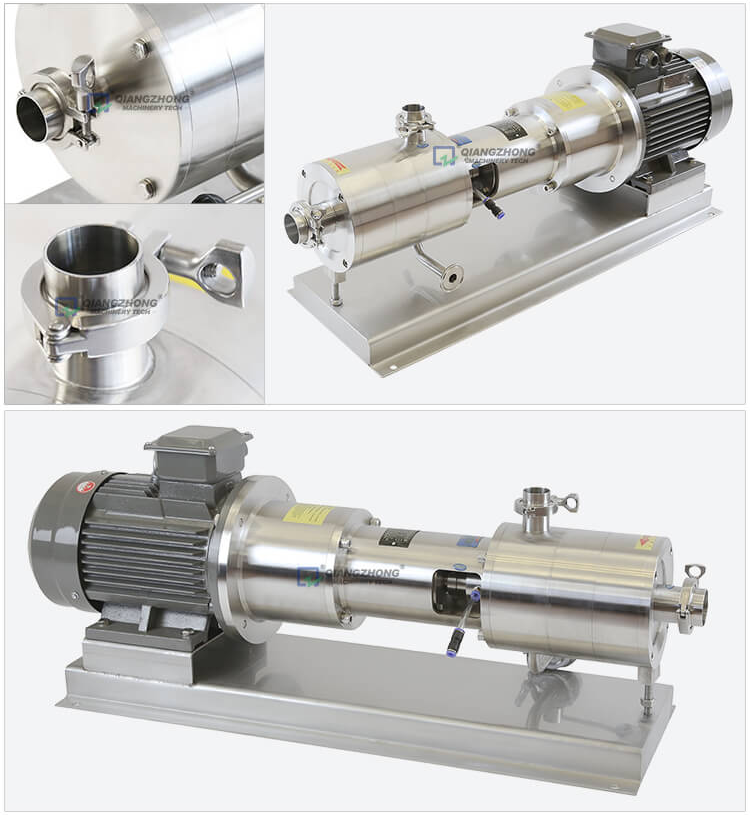

Fanfon emulsification (wanda kuma ake kira a-line high-shear dispersion mixer) babban inganci ne wanda yake hada kayan hadawa, watsawa, ragargazawa, narkewa, lafiya, depolymerizing, homogenization da emulsification, wadanda aikinsu yafi galibi stator da rotator. Na'ura mai juyi yana juyawa cikin sauri don samar da karfi na tsakiya da kuma karfin hydrogen kuma stator ya kasance a tsaye. Ta hanyar madaidaicin haɗuwa da rotor da stator, ana haifar da ƙarfi mai ƙarfi yayin juyawa mai saurin gaske, kuma kayan suna fuskantar tsananin karfi, ƙwanƙwasawa na tsakiya, ɓarkewar tasiri, tashin hankali na ruwa, da rikicewar rikici iri ɗaya. Don haka, kafofin watsa labaru daban-daban kamar su mawuyacin lokaci mai ƙarfi, lokacin ruwa, da lokacin gas ana haɗa su gaba ɗaya kuma ana watsa su da kyau kuma an watsa su nan take. Bayan sake zagayowar sakewa, ana samun ingantaccen samfurin mai inganci.

Nau'in Stator / Rotor

● Rarraba matsakaicin girman kwayar halitta, daidaiton daidaito

● Tare da tazara kaɗan, aikin watsa ƙaramin ƙarfi

Lim Kawar da bambance-bambance masu kyau tsakanin rukuni

Saving Adana lokaci, ingantaccen aiki, tanadin kuzari

● noisearar amo da kwanciyar hankali aiki

● Mai sauƙin amfani, mai sauƙin kulawa

● iya cimma ikon sarrafa kansa

● Babu matattu ƙare, da kayan 100% wuce ta da aka tarwatsa da sheared

Ka'idar aiki

Pampo emulsification pump / in-line high-shear dispersion mixer zai iya ingantaccen aiki, da sauri, kuma a ko'ina ya rarraba daya ko fiye matakai a cikin wani matakin ci gaba, yayin da a cikin yanayin da aka saba matakan ba sa narkewa. Ta hanyar saurin layin hanzari wanda aka samu ta hanyar juzuwar sauri na rotor da kuma karfin kuzari wanda aka kawo ta hanyar karfin inji mai karfin gaske, kayan dake cikin kunkuntar tazarar rotor da kuma stator an tilasta su ne ta hanyar karfi mai karfin inji da kuma karfin lantarki, extrusion na tsakiya, layin ruwa gogayya, tasirin hawaye da tashin hankali da sauran ingantattun sakamako. Wannan yasa rashin daidaitaccen lokaci, lokacin ruwa da kuma lokacin gas mai kama da juna, tarwatsawa da emulsified a karkashin aikin hade na daidai balagagge fasahar da dace adadin Additives. A ƙarshe ana samun samfuran ingantattu masu inganci bayan sake zagayowar maɗaukaki.

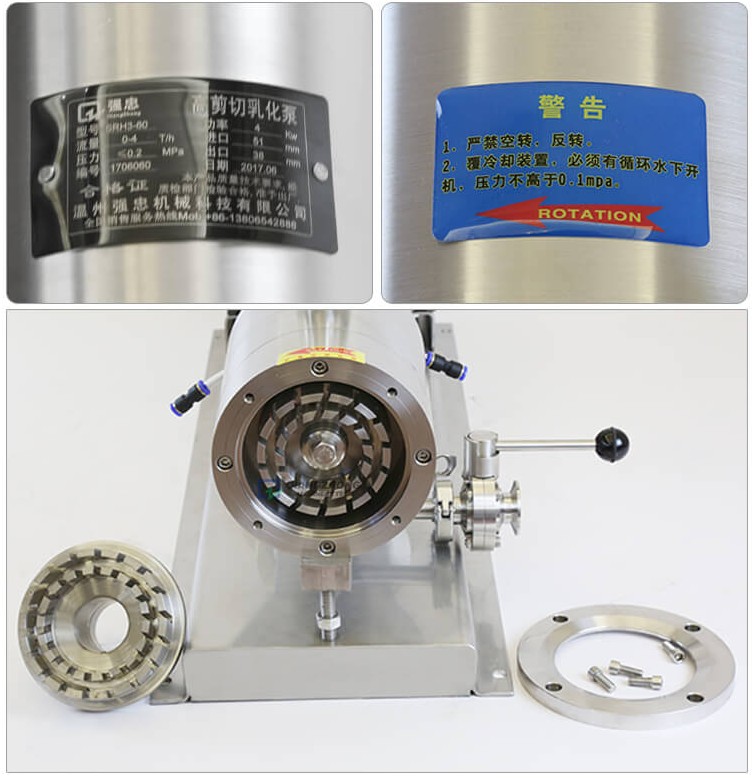

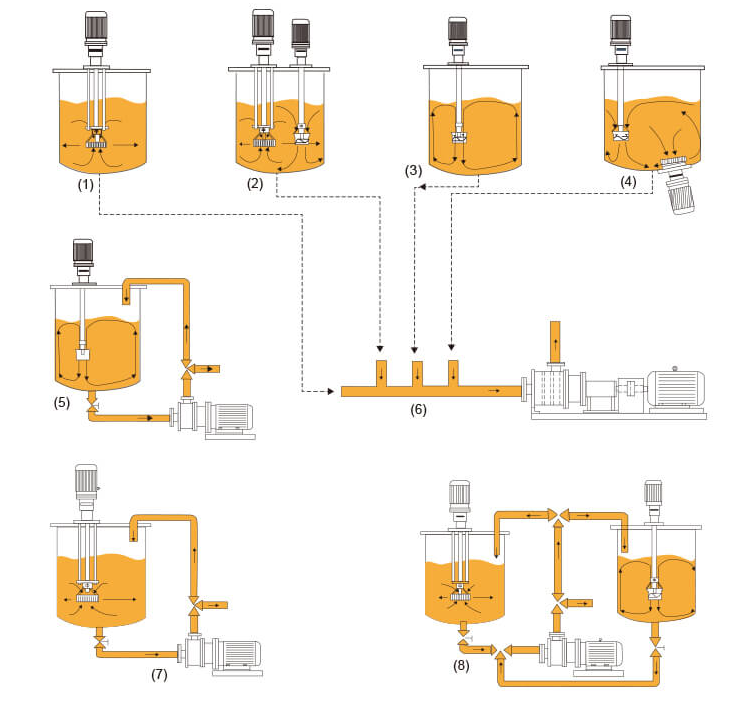

An sanya rukuni uku na stator da rotor a cikin ɗakin aiki na famfon emulsification. Hanyar watsawa a cikin ɗakin aiki yana da kyau. Haɗin na roba yana haɗa motar da sandar a cikin gidaje masu ɗaukewa don haɓaka ƙimar aiki na sandar watsawa. Siffofin hatimi zaɓi ne bisa ga yanayin aiki daban-daban. Ya dace da matsakaici da manyan rukuni na ci gaba da samar da layi ko samar da aikin sake sarrafawa.

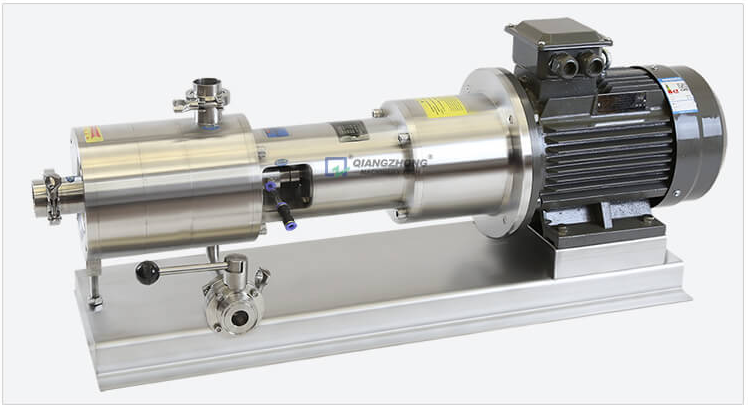

Nunin samfur

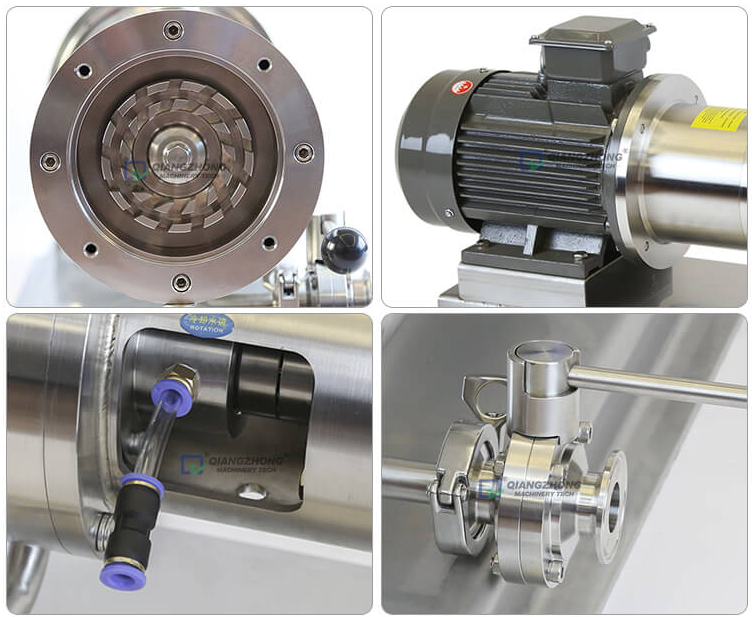

Gear Stator da Rotor High-daidaiton haƙoran hakora da stators nan da nan suna lalata kayan.

Motar tana da fa'idodi da yawa kamar su ƙarfi mai ƙarfi, karfin juzu'i, ƙaramin zafin jiki, ƙarancin faɗakarwa, da dai sauransu. Motar mai-hawa uku kai tsaye tana motsa kan nika don juyawa, yana adana lokacin nika.

Matakan kariya

Pump Fitarwar emulsification ta ɗauki rotor mai saurin sauri da haɗin stator. Underarkashin tuƙin motar, rotor yana kawo ƙarfin kuzari mai ƙarfi tare da saurin layin gaske da tasirin inji mai saurin-mita, wanda ke haifar da abu mai shearing, matse shi sosai, matsatsen ruwa, ya yi tasiri kuma ya tsage a daidai ratar stator da kuma stator. Haɗakarwar rikice-rikice, da sauransu, don cimma tasirin watsawa, nika, emulsification.

● Dangane da buƙatun tsari daban-daban, haɗuwa da na'ura mai juyi da yawa da stator da tsarin hadadden za'a iya daidaita su. Injin yana dauke da adadi mai yawa na sarrafawa, ci gaba da samar da layi, kunkuntar girman kwayar halitta, daidaitaccen tsari, ingantaccen makamashi, karancin kara, aikin barga, kuma babu matattun karshe, kuma kayan sun watse sosai sun kuma aske.

Seal Hatimin inji wani sashi ne wanda rayuwarsa take da alaƙa da yanayin aiki da kiyaye shi. Hatimin inji a kan inji shine dogaro da kayan don sanyaya, saboda haka an hana shi gudu sosai a cikin yanayin shinge na inji ba tare da abu ba, don kar ya lalata hatimin inji. Lokacin da matsakaici ya kasance kayan ƙarfafawa, dole ne a tsabtace kayan cikin ɗakin aiki tare da sauran ƙarfi bayan kowane amfani.

Bincika ko mashin ɗin da famfon shiga yana cikin yanayi mai kyau, kuma ko tarkace, tarkacen ƙarfe, ko wasu abubuwan da zasu iya lalata kayan aikin an haɗa su cikin kayan. Bincika ko dukkan inji, musanman injin, ya lalace idan ana safararsa ko ana shigo dashi. Lokacin haɗawa da maɓallin wuta, don Allah a tabbatar cewa an riga an shigar da na'urar lantarki mai tuntuɓar na'urar tsaro.

● Kafin haɗawa da masarrafar kayan aiki da bututun kayan aiki tare da bututun aiki, dole ne a tsabtace bututun aikin. Bayan tabbatar da cewa bututun aikin ba shi da walda mai walda, kwakwalwan karfe, kwakwalwan gilashi, yashi ma'adini da sauran kayan da suke cutarwa ga kayan aikin, ana iya haɗa shi da injin. Ana buƙatar matsayi na shigarwa da akwati a matakin tsaye. Matsayin shigarwa ya zama a tsaye ga akwati. Idan an girka shi a hankali, dole ne a kulle shi sosai kuma a kiyaye shi daga danshi, ƙura, laima, da fashewa.

● Kafin fara inji, haɗa ruwan sanyaya na hatimin inji. Lokacin rufewa, kashe wutar sannan ka yanke ruwan sanyaya. Ruwan sanyaya na iya zama ruwan famfo, kuma ruwan sanyaya yana ≤ 0.2Mpa. Dole ne a kunna wuta bayan kayan sun shiga dakin aiki, kuma baza ayi aiki da inji ba idan babu abu don hana hatimin inji ya kone saboda tsananin yanayin zafi ko kuma ya shafi rayuwar sabis.

Tabbatar da cewa juyawar motar ya yi daidai da juyawar juyawa da aka yiwa alama akan sandar juyawa kafin kunna na'urar, kuma an hana motar yin aiki a cikin akasin hakan. Yayin aikin inji, dole ne a ciyar da kayan ruwa gaba ɗaya ko a cikin wani adadi a cikin akwatin. Injin ya kamata ya zama ba shi da izini don kaucewa zafin jiki mai ƙarfi ko ƙarfaffen lu'ulu'u na kayan a cikin ɗakin aiki da lalata kayan aikin.

Is Ana amfani da famfo don emulsification, homogenization da watsa abubuwa a cikin masana'antar masana'antu. Injin ya kunshi yadudduka uku ko sama da biyu. Bayan an tsotsa kayan a cikin rotor, ana fuskantar da dubban daruruwan ayyukan sausayawa, kuma an aske shi, an tarwatsa shi, kuma an watsa shi a cikin yadudduka ta yadda ruwa mai yawa yana tarwatse sosai kuma tsayayyun ƙwayoyin suna cikin hanzari.