Sashin Fasaha

Tsarin Samfura

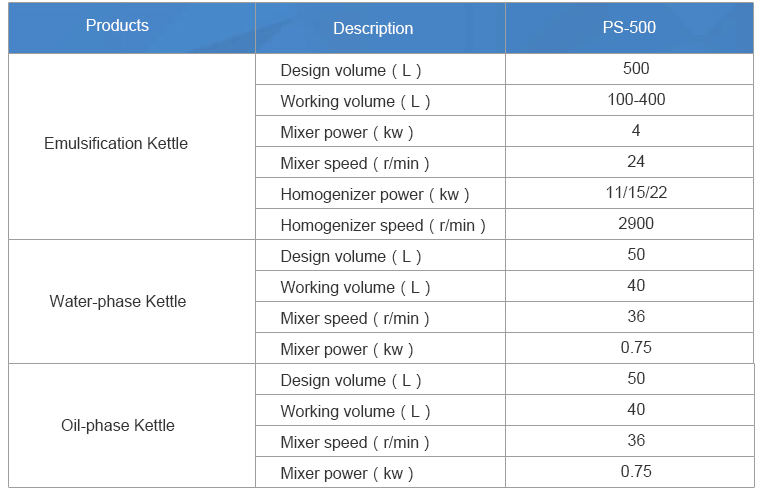

An tsara tsarin emulsification don samar da dakatarwar emulsion don yawancin masana'antu. Akwai nau'ikan zaɓuɓɓuka guda 5 waɗanda suka fito daga 5L zuwa 1000L, gami da gwaji, matsakaici da kuma girman girma.

Tsarin yana da sauki a cikin tsari kuma yana da saukin aiki, kuma dukkan inji yana da tsaran sararin samaniya dangane da tsarin tsayi. Abubuwan haɗin hadawa na ci gaba suna ba da tabbacin ingancin ƙirar samfurin. Yana da yawa kuma ana iya amfani dashi tare da nau'ikan kayan aiki kamar injin, dumama jaket / sanyaya, lids masu buɗewa da yawa, ƙirar samfur, da sauransu.Yana sanya tsarin SP ya zama na'urar da ta dace don sarrafa ruwaye. Yana da sassauƙa a cikin zane kuma ana iya daidaita shi bisa ga bukatun masana'antu daban-daban. Ana iya amfani dashi a cikin emulsion da kuma samar da magani a cikin masana'antar kwalliya, a cikin samar da mayonnaise da kayan ƙanshi a masana'antar abinci, a cikin samar da emulsions, dakatarwa, launuka masu launi da sutura a masana'antar sinadarai, da sauransu.

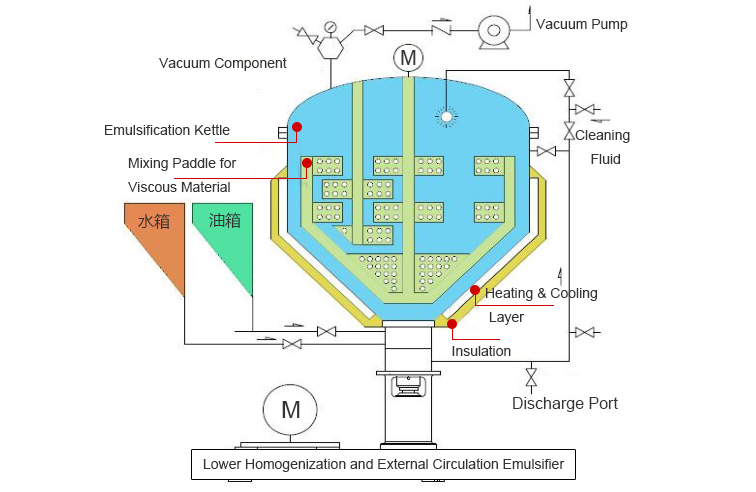

Tsarin da Gudanar da Aiki

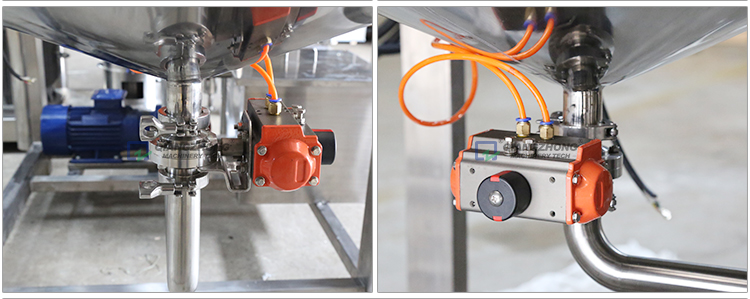

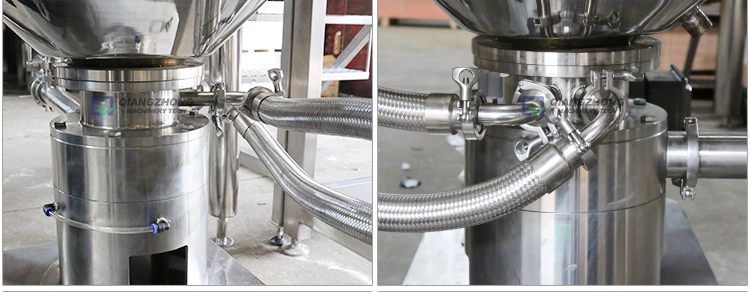

Tsarin hadewar kewaya na waje shine asalin tsarin. Yana haɗawa da inhalation, jigilar kaya, watsawa, da tsabtace CIP akan layi. Tsarin famfon-mataki biyu yana ba da damar tsarin hadewa don samar da karfi ba kawai don cakuda kayan ba, amma har da karfin yin famfo mai karfi da kuma karfin sadar da abubuwa masu danko sosai. Yana ba da damar lokaci mai ruwa-ruwa da kuma lokacin mai da za a emulsified kai tsaye a cikin tsarin homogenization, sannan a tura su zuwa mahaukatar don tashin hankali, saboda haka guje wa lahani da aikin al'ada ya haifar.

Wannan tsarin ingantaccen tsari ne wanda ya haɗu da kayan aiki mai kyau, daidaiton kayan ƙira da girman emulsification. Za a iya ƙara daskararru da ruwa kai tsaye zuwa kan emulsification kai tsaye da sauri kuma gaba ɗaya emulsified kuma a watse don kauce wa agglomeration. A cikin tsarin tsaftace CIP, ana iya amfani da tsarin azaman famfon canja wuri don samar da ruwa mai tsafta mai tsafta don juyawa kwallayen juyawa.

- Ana ƙara matakan emulsification da watsawa kai tsaye zuwa kan shugaban aiki.

- Designirar ƙirar sandar ƙwanƙwasa ta dace don kiyayewa da rarrabawa.

- Tsarin wurare, tsabtace CIP, ba a buƙatar ƙarin fanfuna don fitarwa.

- Zaɓin zaɓi na kyauta ko kayan zasu wuce ta cikin ɗakin emulsification.

- Sakamakon aiki mafi kyau, gajeren lokacin aiki.

Babban tsarin emulsification za'a iya hada shi tare da hoppers daban-daban, masu gabatar da shirye-shirye da fitarwa tankokin ajiya dangane da bukatun samarwa. Dangane da kayan, ana iya ƙara na'urorin dumama da sanyaya daban. Hatta layin zagayawa na iya wuce tururi kai tsaye don ɗora kayan. Efficientarin inganci shine cigabanmu koyaushe.

Wannan rukunin sarrafa wutar lantarki ana iya daidaita shi tare da sarrafa maɓallin mai sauƙi ko tsarin allon taɓa PLC tare da sarrafa girke-girke, gwargwadon zaɓin abokin ciniki. Ana iya samun kayan aikin hannu ko cikakke ta atomatik akan buƙata.

Idan aka kwatanta da nau'in kayan aiki iri ɗaya a ƙasashen waje, tsarinmu na atomatik ba zai iya biyan bukatun aikin abokin ciniki kawai ba (zai iya samar da tsarin gwaji mai sauƙi), amma kuma yana da manyan fa'idodi dangane da farashi, lokacin isarwa da sabis ɗin bayan-tallace-tallace.

Nunin samfur